Polymer machining is a specialized form of machining that involves the use of polymer materials, such as polyethylene, polypropylene, nylon, and other polymers. To ensure that projects involving polymer machining are safe and successful, it is important to adhere to specific guidelines and best practices.

Here are some benefits:

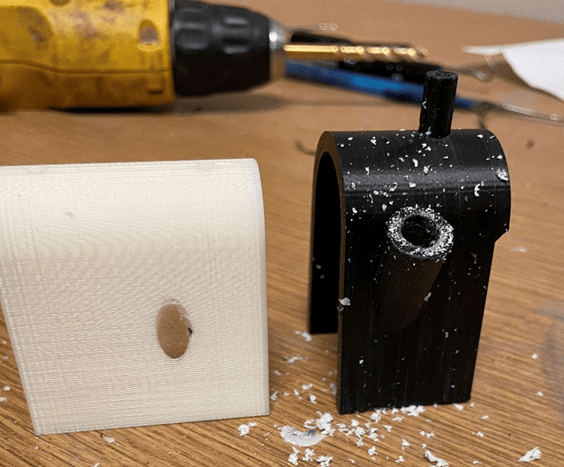

The first guideline for polymer machining to follow is understanding the properties of the polymer being machined. Each type of polymer has unique characteristics that must be taken into consideration. Some polymers are more brittle than others, so the cutting tools used must be designed accordingly.

Image Source: Google

In addition to understanding the properties of the polymer, it is also important to consider the type of machining being done. Different types of machining require different cutting tools and techniques.

This is especially true for complex parts that require the use of multiple tools and operations. If the machining requires the use of high-speed drills and end mills, then the cutting tools must be designed to withstand the rigors of the process.

Finally, it is important to consider the safety of the machining process. This includes both the safety of the operator and the safety of the machine. Properly designed cutting tools, safety guards, and other protective measures can help to reduce the risk of injury or damage to the machine or the operator.

By following the above guidelines, projects involving polymer machining can be successful and cost-effective.

/cdn.vox-cdn.com/uploads/chorus_image/image/51867435/Eli_Preferred_Headshot.0.jpeg)